Field Studies of Energy Savings and Heat Load Reduction

Case Studies, Pictures, Videos, and More

EnviroCoatings are Lab Tested and Real World Certified

Cool Wall and Cool Roof Products

Reducing energy use saves money.

Plain and simple.

In spite of extensive Lab Testing, Approvals, Certifications, and Ratings by Industry Bodies, Customers want to know what proof do we have that they can reduce heat load and therefore cut energy use by applying Ceramic InsulCoat Wall and/or Ceramic InsulCoat Roof on their building? Does a Cool Wall work? Does a Cool Roof work?

Those are fair questions.

In response, we set out to conduct Field Studies of Ceramic InsulCoat Wall and Roof applications and provide Pictures, Video and Case Studies to support our findings. We have completed a few and will continue to collect and publish results.

We present this empirical data for your review:

Ceramics in Everyday Life

Ceramic InsulCoat Wall and Ceramic InsulCoat Roof are Ceramic filled!

EnviroCoatings has taken out the cheap fillers found in most paints and coatings today. We replaced these with Cerylium, a combination of high quality raw materials that includes hollow-core ceramic microspheres, strands, and irregular particulate.

Cerylium is a technically advanced process that combines never - before - utilized components into a proprietary formula of 23 - precision blended, high performance ingredients, in a complex, 100% acrylic suspension.

The American Ceramic Society

Have you ever considered just how Ceramics play a part in so many Industries and how that affects everything we do? Visit: The American Ceramic Society.

Published Case Studies

Ceramic InsulCoat Wall: Residential Cool Wall Energy Savings Case Study - Tempe, Arizona

----------------------------------------

Ceramic InsulCoat Wall: Cool Wall Case Study - U.S. Marine Corps Base Camp Pendleton, California

Residential Case Study in Progress

Ceramic InsulCoat Wall: Tracking a Residential Property in Buckeye, Arizona

June 2016

We would like to introduce Mr. Chris Davis from Buckeye, Arizona. He explains in the video why he selected Ceramic InsulCoat Wall for his Stucco Home.

Is EnviroCoatings truly a Cool Wall Coating or Cool Wall Paint? Stayed tuned.

The Davis Family has agreed to participate in a Multi-Year Case Study to track their energy use before and after the application of Ceramic InsulCoat Wall. We will provide periodic updates.

----------------------------------------

Federal Government Case Study in Progress

Ceramic InsulCoat Roof: Government Tracking Results on Residential Properties

SERC (Sustainable Energy Resources for Consumers) Pilot Projects

EnviroCoatings Ceramic InsulCoat Roof was selected to participate with the U.S. Department of Energy on SERC Pilot Projects in 2011. The purpose of the SERC Pilot Projects is to test the effectiveness of Cool Roof technologies on residential properties.

The SERC Cool Roof criteria has eight requirements for field-applied liquid coatings to meet in order to be considered for the Pilot Projects. These include having a ceramic content; minimum solar reflectance and thermal emittance ratings; an active participant with the Cool Roof Ratings Council (CRRC); and an Energy Star® Partner.

Ceramic InsulCoat Roof has been applied to over 30 residential properties in Virginia and West Virginia. The projects are being coordinated by Oak Ridge National Laboratory.

Oak Ridge National Laboratory will conduct home inspections, occupant surveys, track energy use, and conduct billing analyses. They will publish the results in the Fourth Quarter of 2012.

NOTE

Update: May 2012

Due to the mild winter of 2011-2012 in the Eastern United States, the Department of Energy determined that data collected would not indicate achieved results for a "typical" winter.

Consequently, the SERC Pilot Projects will be tracked for another winter season. Results are scheduled for release in late 2013.

NOTE

Update: September 2013

According to the Department of Energy, SERC evaluations have not been provided at this

time. Results are still scheduled for release in late 2013.

NOTE

Update: April 2016

The SERC Report is still in final review and should be released later this year.

Pictures and Video

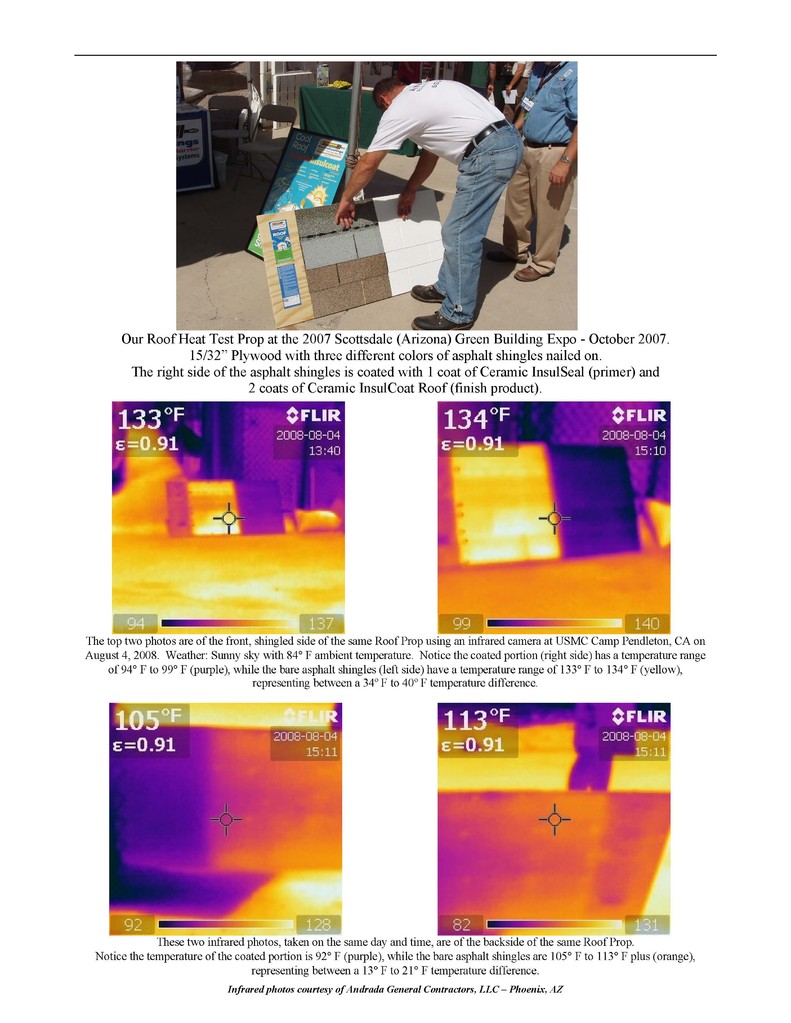

Thermal Imagining of "The Cool Roof Prop"

----------------------------------------

Video - Cool Roof Reduced Attic Temperatures: Fallbrook, California

March 2016 Video of a Sloped Asphalt Shingle Roof System on a Residential Home

----------------------------------------

Video - Cool Roof Heat Load Reduction: Houston, Texas

July 2013 Video of a Flat, Modified Bitumen (Built-Up BUR) Roof System

on a Multi-Story Hotel

----------------------------------------

Infrared Thermometer Pictures - Commercial BUR Roof

An Excellent Depiction of Heat Gain and a Cool Roof on an Asphalt Roofing System

These are time-lapse pictures taken May 3, 2011 on a commercial asphalt roofing system in San Diego, California. Conditions that day were: 75°F, with a Bright, Sunny Sky.

As the Sun climbs in the sky over a 5-hour period from 7:45AM to 12:40PM, notice how the asphalt portion of the roof quickly heats from 62°F to 142°F. That is a rise of 80 degrees Fahrenheit in five hours!

(Think about Solar Reflectance and Thermal Emmittance)

The first coat of Ceramic InsulCoat Roof had been applied next to where we were taking pictures, so we compared temperatures side by side

at 12:40PM.

The Asphalt roof membrane was 142°F and two feet away,

one coat of Ceramic InsulCoat Roof was 90°F. That is a surface temperature difference of 52 degrees Fahrenheit!

Another "Cool Roof."

----------------------------------------

Video - Metal Cool Roof: Roof Temperature Comparison

Integrity Energy Solutions - South Carolina - May, 2011

This video featuring Jonathan Elkin of Integrity Energy Solutions in South Carolina, was taken on May 16, 2011.

Notice the temperature difference, with just a single coat of Ceramic InsulCoat Roof applied.

Interested in Participating in a Field Study?

Ceramic InsulCoat Wall and Ceramic InsulCoat Roof Projects

We will continue to collect empirical data from the field. Any building, any climate, any substrate, any location.

For Non-Residential Building Customers, we can actually track energy use through the EPA Energy Star® Portfolio Manager system. Not only will you be able to track energy use and costs, but you may also qualify for local utility rebates and local, state and federal tax incentives today and/or in the future.

Interested? Contact our Sales and Technical Support Group.

Spread the Word: